High speed air metal saws are essential tools for cutting various metals efficiently. They operate using compressed air, which allows for powerful and precise cutting capabilities. This feature makes them popular in industrial settings as well as for DIY enthusiasts.

These saws are designed to handle a wide range of materials, including steel, aluminum, and other alloys. The lightweight design and portability enhance their usability across different work environments.

Moreover, air-powered saws produce less heat compared to electric saws, reducing the risk of warping the material being cut. Their ability to maintain high speeds ensures clean, smooth cuts, making them an excellent choice for various metalworking projects.

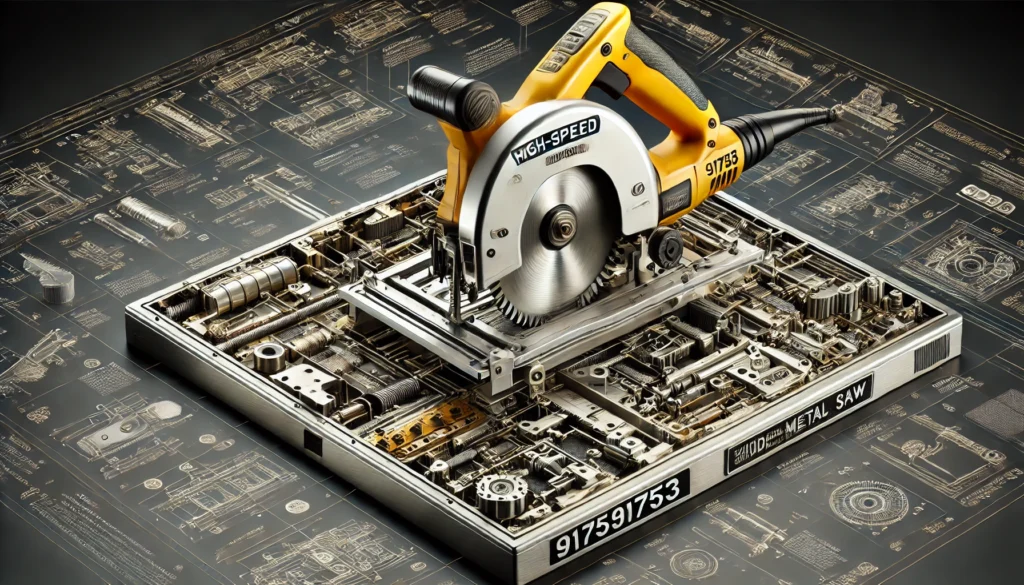

Key Features of the High Speed Air Metal Saw Model 91753

The High Speed Air Metal Saw Model 91753 comes equipped with several standout features. Its robust motor delivers high RPMs, allowing for fast and efficient cutting of metals up to 1/4 inch thick.

- Lightweight Design: The saw is easy to handle, making it suitable for prolonged use without causing fatigue.

- Adjustable Speed Control: Users can set the speed according to the material and cutting requirements, ensuring optimal performance.

- Durable Construction: Built from high-quality materials, this model is designed to withstand heavy usage in demanding environments.

These features collectively contribute to a reliable and efficient cutting experience, making the Model 91753 a preferred choice among professionals and hobbyists alike.

High Speed Air Metal Saw Model 91753 Manual: Setup Instructions

Setting up the High Speed Air Metal Saw Model 91753 is straightforward. Begin by unpacking the saw and ensuring all components are included as per the manual. Check for any visible damage before proceeding with the setup.

Next, connect the saw to an air compressor, ensuring that the compressor is set to the recommended PSI level for optimal performance. It’s essential to use the correct fittings to avoid air leaks.

- Blade Installation: Install the appropriate blade for the material you plan to cut, following the instructions in the manual. Ensure the blade is securely fastened.

- Safety Checks: Before starting the saw, check all safety features and ensure the workspace is clear of obstructions.

Once everything is set up and checked, the saw is ready for use, providing a safe and efficient cutting experience.

Operating Procedures from the High Speed Air Metal Saw Model 91753 Manual

Operating the High Speed Air Metal Saw Model 91753 requires attention to safety and technique. Always wear appropriate personal protective equipment (PPE), including goggles, gloves, and hearing protection.

When starting the saw, ensure that you have a firm grip and a stable stance. Begin with the blade slightly above the material to avoid binding. As you lower the blade onto the material, apply steady pressure to maintain a consistent cut.

- Cutting Technique: Keep the saw moving at a steady pace to achieve clean cuts. Avoid forcing the saw through the material, as this can lead to uneven cuts and premature blade wear.

- Material Positioning: Secure the material being cut using clamps to prevent movement during the cutting process.

Following these operating procedures will enhance the efficiency and safety of your cutting tasks.

High Speed Air Metal Saw Model 91753 Manual: Maintenance Tips

Regular maintenance of the High Speed Air Metal Saw Model 91753 is crucial for its longevity. Start by cleaning the saw after each use to prevent metal shavings and debris from accumulating. A clean saw operates more efficiently and safely.

Check the air filters periodically and replace them as needed to ensure optimal airflow. Blocked filters can reduce performance and increase wear on the motor.

- Blade Inspection: Regularly inspect the cutting blade for signs of wear or damage. Replace blades that are dull or nicked to maintain cutting efficiency.

- Lubrication: Lubricate moving parts according to the maintenance schedule in the manual to prevent friction and extend the life of the tool.

Implementing these maintenance tips will help keep your saw in top condition and ready for any project.

Common Issues and Troubleshooting Tips

Users of the High Speed Air Metal Saw Model 91753 may encounter some common issues. One frequent problem is difficulty starting the saw, often caused by low air pressure or an improperly connected air hose.

Another issue is uneven cuts, which can occur if the blade is dull or installed incorrectly. Regularly checking the blade and ensuring it is sharp will prevent this problem.

- Air Leaks: Inspect hoses and fittings for air leaks, which can decrease performance. Tighten connections and replace worn hoses as necessary.

- Vibration: Excessive vibration during operation may indicate an unbalanced blade. Ensure the blade is installed correctly and is in good condition.

Addressing these common issues through troubleshooting can enhance the performance and reliability of the saw.

Safety Precautions When Using High Speed Air Metal Saws

Safety should always be a priority when using high speed air metal saws. Before starting, ensure that you are wearing appropriate personal protective equipment (PPE), including safety glasses, gloves, and ear protection.

Always operate the saw in a well-ventilated area to avoid inhaling metal dust. Keep the workspace free of clutter and distractions to maintain focus while cutting.

- Avoid Loose Clothing: Ensure that your clothing and hair are secured to prevent them from getting caught in the saw.

- Emergency Procedures: Familiarize yourself with the emergency shut-off procedures for the air compressor and saw in case of an accident.

Following these safety precautions will help prevent accidents and injuries while using the saw.

Effective Cutting Techniques for the High Speed Air Metal Saw Model 91753

To achieve optimal results with the High Speed Air Metal Saw Model 91753, employing effective cutting techniques is essential. Start by marking the cutting line clearly on the material to guide your cuts accurately.

When cutting, maintain a steady pace and let the saw do the work. For thicker materials, make multiple passes rather than forcing the saw through in one go. This approach minimizes strain on the motor and reduces blade wear.

- Angle Cutting: For angled cuts, use a miter gauge or guide to ensure precision. This technique is especially useful for creating clean, accurate angles.

- Cooling: If cutting through thick or dense material, consider using a coolant to prevent overheating of the blade.

Implementing these cutting techniques will enhance the quality of your work and improve overall efficiency.

Accessories to Enhance Performance of the High Speed Air Metal Saw Model 91753

Several accessories can improve the performance of the High Speed Air Metal Saw Model 91753. Using the right blade for the specific material you are cutting is crucial for achieving clean results.

- Dust Collection Systems: Consider using a dust collection attachment to keep the workspace clean and reduce inhalation of metal particles.

- Blades Variety: Investing in a variety of blades (e.g., carbide-tipped, high-speed steel) can provide versatility for different cutting tasks.

These accessories not only enhance the functionality of the saw but also improve the overall user experience.

User Experiences and Reviews of the High Speed Air Metal Saw Model 91753

User feedback on the High Speed Air Metal Saw Model 91753 highlights its efficiency and reliability. Many users appreciate the saw’s lightweight design, which allows for easy maneuverability without sacrificing power.

Customers often note the effectiveness of the adjustable speed control, enabling them to customize the cutting process for various materials. However, some users have mentioned that proper maintenance is crucial for optimal performance.

- Positive Experiences: Users frequently commend the saw for its clean cuts and ease of use, particularly in tight spaces.

- Suggestions for Improvement: Some reviewers suggest adding more detailed troubleshooting guidance in the manual for common issues.

Overall, user experiences indicate a high level of satisfaction with the model, reinforcing its reputation as a reliable tool for metal cutting.

Comparative Analysis: High Speed Air Metal Saw Model 91753 vs. Other Models

When comparing the High Speed Air Metal Saw Model 91753 Manual to other models on the market, several factors come into play. Its lightweight design and high RPM capabilities make it a strong contender among air-powered saws.

Compared to electric models, the 91753 offers greater portability and less heat generation during operation. This advantage makes it particularly appealing for users working in various environments.

- Performance Metrics: The cutting depth and speed of the Model 91753 generally outperform many competitors in similar price ranges.

- User Satisfaction: Customer reviews often highlight the reliability and ease of use as key differentiators from other models.

This comparative analysis underscores the High Speed Air Metal Saw Model 91753 as a valuable investment for both professionals and DIY enthusiasts.

Conclusion: Maximizing Efficiency with the High Speed Air Metal Saw Model 91753 Manual

In conclusion, understanding the features and best practices for the High Speed Air Metal Saw Model 91753 can significantly enhance its performance. Regular maintenance, proper setup, and adherence to safety protocols are vital for achieving the best results.

By utilizing effective cutting techniques and suitable accessories, users can maximize the saw’s efficiency and lifespan. Additionally, learning from user experiences and feedback can inform better practices and improve overall satisfaction.

Incorporating these insights will ensure that the High Speed Air Metal Saw Model 91753 remains a reliable tool for all metal cutting needs. Emphasizing safety and maintenance will not only enhance performance but also ensure a safer working environment.