A well-functioning commercial cool room is essential for businesses across the food, hospitality, and healthcare sectors. These systems play a crucial role in maintaining the safety, quality, and shelf life of temperature-sensitive goods such as fresh produce, dairy products, meat, and pharmaceuticals.

Conversely, when a cool room fails to maintain the correct temperature, the consequences can be dire: stock loss, operational downtime, and potential health compliance issues are just a few of them. Thus, it’s important to ensure that it is always running at optimal levels.

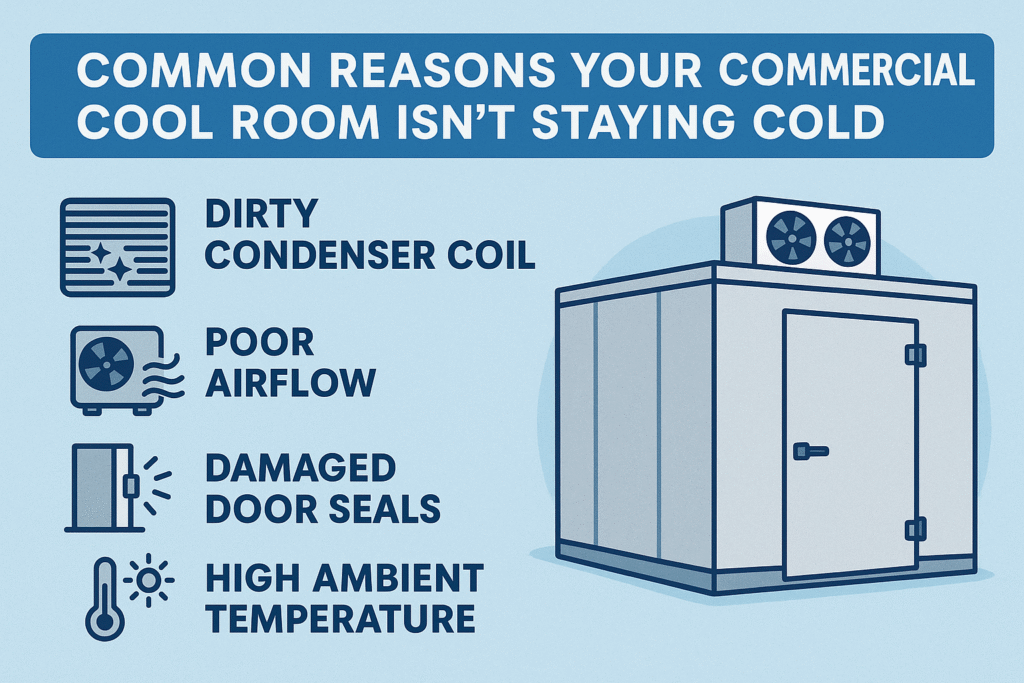

While there are many reasons that a cool room may be losing its chill, most boil down to just a few common factors. Here’s the top five you need to keep an eye out for.

Refrigerant Leaks

Refrigerant — the fluid that absorbs and transfers heat — is vitally important for the cooling cycle. When holes occur in a cool room’s system, such as due to corroded lines, failed joints, or accidental damage during maintenance, refrigerant escapes and the stored levels drop.

Less refrigerant means heat transfer is also less efficient. This forces the system to work harder, making it more difficult for a cool room to maintain a consistent temperature. Any discovered leak should be rectified as soon as possible to prevent further performance loss, but it’s best handled by professionals experienced in cool room and commercial refrigeration repairs.

Pro tip: Schedule routine pressure checks as part of your maintenance plan. A sudden drop in pressure is often the first sign of a hidden leak – long before visible symptoms appear.

Faulty Compressor

The compressor, often referred to as the ”heart” of a refrigeration system, is responsible for circulating refrigerant and maintaining system pressure. If it fails or begins to degrade, the entire cooling cycle can become compromised.

Common causes of compressor issues include overheating, mechanical wear, and electrical faults. Early warning signs often manifest as unusual noises – such as rattling or clanking – or a noticeable drop in cooling performance.

Pro tip: Avoid short-cycling (frequent on-off cycling), which places excessive strain on the compressor and significantly shortens its lifespan.

Dirty Condenser Coils

Condenser coils perform an important role in a commercial cooling room by expelling heat from the system. However, because they’re typically located on the bottom or at the back of the walk-in refrigerator, it’s easy for them to accumulate grease, dirt and dust — especially in kitchens or food storage areas.

Any buildup of dirt and grime on the coils acts like a form of insulation, meaning that the coils have to work harder to exchange heat from the refrigerant into the surrounding air. Not only does this additional strain increase energy use, but it can also lead to overheating or premature breakdown of the cool room if not addressed.

Pro tip: Check periodically whether the area around the condenser feels unusually hot or the fan runs constantly. If this seems to be the case, the coils may be overdue for cleaning.

Worn-Out Door Seals

Commercial cool rooms are designed to be airtight. The door seals (also known as gaskets) create a hermetic barrier that helps regulate internal temperature. Over time, they can crack, become brittle, or loosen due to constant wear and temperature fluctuations.

When seals fail, warm air enters the cool room, leading to condensation, frost buildup, mould growth, and reduced cooling efficiency. This forces the system to run longer and harder than necessary to maintain the necessary temperatures.

Pro tip: Test your door seals by closing the door on a sheet of paper – if it slides out easily, the seal may no longer be effective.

Overloaded or Poorly Arranged Storage

Like any regular refrigerator, it’s essential for a commercial cool room to have unrestricted airflow. Overcrowding shelves, blocking vents, or stacking items too tightly against walls can prevent cold air from circulating evenly in the space.

Any inefficiencies in circulation due to improper storage practices can result in temperature inconsistencies or “hot spots” within the cool room. As a result, products placed in these spots may not be adequately chilled, which can increase their spoilage risk. Additionally, it can also put the system under unnecessary strain as it has to work harder to correct these hotspots.

Pro tip: Keep shelving at least 5-10 cm from walls, and ensure vents remain unobstructed to allow free air circulation and consistent internal temperatures.

Stay Ahead of Cool Room Failures Before They Start

If your commercial cool room struggles to maintain consistent temperatures, you may face everything from inventory loss and compliance breaches to unexpected downtime and soaring energy costs.

Fortunately, cool room troubles are often preventable via regular inspections and timely commercial refrigeration repairs. Addressing early warning signs helps prevent costly disruptions, extends equipment lifespan, and protects both your stock and bottom line.

Think your cool room could use a service? Consult with your local cool room and commercial refrigeration repair specialist today for improved performance and peace of mind.