A prominent European industrial foundry, specializing in critical aerospace components, has announced a significant expansion of its production capabilities. The facility has commissioned three state-of-the-art Vacuum Induction Melting (VIM) furnaces from SECO/WARWICK, specifically designed to manufacture high-performance parts for next-generation jet engines.

The aerospace sector is currently witnessing a technological shift, demanding materials that can withstand increasingly extreme operating temperatures. To meet this challenge, the foundry’s new investment focuses on the production of nickel and cobalt superalloys using advanced casting techniques.

Precision Casting for the “Hot Section”

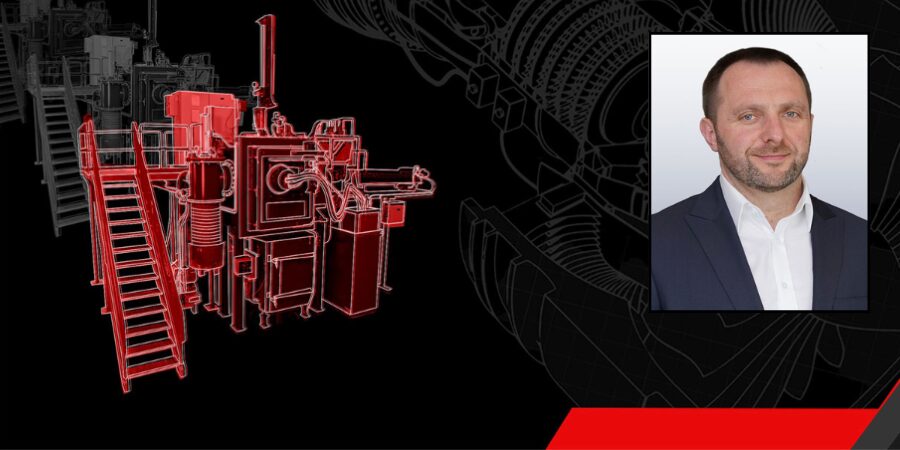

The order comprises three specialized furnaces capable of Directional Solidification (DS) and Single Crystal (SC) casting. These technologies are vital for creating the turbine blades found in the “hot section” of modern aircraft engines.

Unlike traditional casting, Single Crystal technology eliminates grain boundaries within the metal. This results in components that offer superior resistance to thermal fatigue and creep, allowing jet engines to burn fuel more efficiently at higher temperatures.

Key capabilities of the new VIM units include:

- Capacity: A maximum charge weight of 40kg, optimized for precision component production.

- Versatility: Capable of handling both nickel and cobalt-based superalloys.

- Design: Engineered to facilitate complex crystallographic structures required for flight-critical hardware.

“In the VIM DS/CS furnace, the client can obtain castings using directional solidification or single crystal technology. The well-designed furnace structure allows the user to produce the highest quality castings,” said Sławomir Woźniak, CEO of the SECO/WARWICK Group. “This equipment ensures that the foundry can meet the rigorous quality standards demanded by global engine manufacturers.”

A Comprehensive Portfolio for Aerospace

While this specific order highlights SECO/WARWICK’s leadership in vacuum metallurgy, the Group’s influence on the aviation industry extends across multiple thermal processing disciplines.

Modern aircraft require a diverse range of manufacturing technologies. While VIM furnaces are essential for turbine blades, the Group also provides critical solutions for the production of aviation heat exchangers. For instance, the company is a global leader in the controlled atmosphere brazing of aluminum, a process essential for manufacturing lightweight, high-efficiency cooling systems used in both commercial and defense aircraft. This breadth of expertise allows SECO/WARWICK to support the aerospace supply chain at every level, from the engine core to thermal management systems.

Vacuum Metallurgy: The Future of Flight

The decision to invest in these three furnaces reflects a broader trend in the aviation market. As engine manufacturers push for better fuel economy and lower emissions, the demand for “perfect” materials grows.

Vacuum metallurgy is no longer a niche process; it is a necessity. By controlling the melting and solidification environment in a vacuum, manufacturers can eliminate impurities and achieve the specific mechanical properties required for flight. This installation ensures the European partner remains at the forefront of this high-tech manufacturing race.