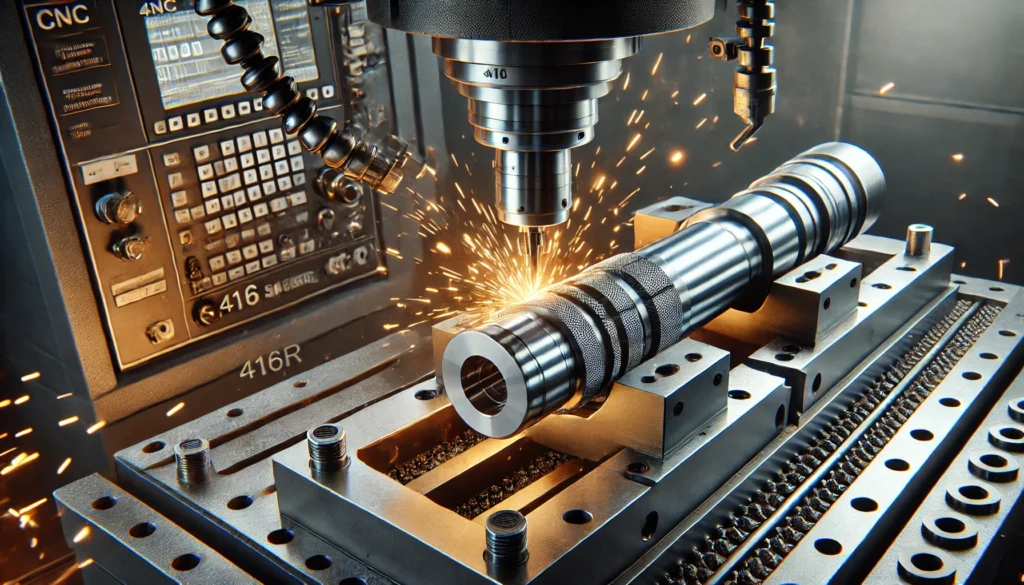

When it comes to firearms, precision and reliability are essential, especially for compact weapons designed for everyday use. The CNC machined steel Armory Craft – carry size components are engineered to enhance the performance, durability, and accuracy of carry-size firearms. Known for their expertise in CNC machining, Armory Craft uses cutting-edge technology and high-quality materials like 416R stainless steel to produce parts that meet the highest standards. Let’s explore what makes CNC machined steel Armory Craft – carry size components a trusted choice for firearm enthusiasts and professionals alike.

What is CNC Machining?

CNC (Computer Numerical Control) machining is a manufacturing process where computers control tools to create precise parts. This technology ensures components are crafted to exact specifications, with minimal room for error. The process allows for high repeatability, making CNC-machined parts incredibly reliable and consistent in performance. This precision is especially critical for firearms, where even the smallest flaw can affect functionality.

Materials Used in Armory Craft Products

One of the standout features of Armory Craft products is their use of high-grade 416R stainless steel. This material is not only strong and durable but also highly resistant to corrosion, making it perfect for firearms. Additionally, 416R stainless steel is easy to machine, ensuring a smooth, high-quality finish. These characteristics set it apart from other materials commonly used in firearm components.

Key Components for Carry-Size Firearms

Armory Craft produces a range of CNC-machined parts tailored for compact firearms. Some of the most notable components include:

- Barrels:

CNC-machined barrels are designed for precision shooting. For example, their threaded barrels come with protectors that safeguard the threads, ensuring long-term usability and reliability. - Magwells:

Magwells are essential for fast and smooth reloading. Armory Craft’s magwells are CNC-machined from solid steel billets, providing a superior fit compared to factory-made or MIM (Metal Injection Molding) parts. - Triggers and Accessories:

CNC machining allows for ergonomic designs and ensures parts are reliable under all conditions, making them ideal for carry-size firearms.

Features and Benefits of CNC Machined Steel Components

For those who carry firearms daily, durability and reliability are crucial. CNC-machined steel components offer numerous advantages:

- Enhanced Durability: These parts are built to withstand everyday wear and tear.

- Improved Fit and Finish: Precision machining ensures a seamless fit, leading to better performance and aesthetics.

- Lightweight Design: Despite being made of steel, these components are crafted to balance strength and portability, making them ideal for compact firearms.

Applications for Carry-Size Firearms

CNC-machined components are particularly beneficial for carry-size firearms, as they improve reliability and accuracy—two critical factors for self-defense. Whether you’re at the range or in a high-pressure situation, these parts ensure your firearm functions smoothly and consistently.

Maintenance and Longevity

CNC-machined parts not only perform well but are also easy to maintain. The high-quality materials and precise construction ensure that these components last for years with minimal upkeep, providing excellent value for firearm owners.

Comparison with Standard Components

How do CNC-machined parts compare to standard factory or MIM components? The answer lies in precision and durability. While factory parts are often mass-produced and may lack the fine-tuned quality of CNC-machined components, MIM parts can sometimes fall short in strength. CNC machining ensures a perfect fit, robust performance, and a polished finish, making it the superior choice for firearm enthusiasts.

The Last Words on CNC machined steel Armory Craft – carry size

CNC-machined steel components from Armory Craft are a game-changer for carry-size firearms. From barrels to magwells, these parts are crafted with precision and durability in mind, ensuring enhanced performance for everyday carry. If you’re looking to upgrade your firearm with high-quality, reliable parts, Armory Craft’s CNC-machined steel components are a perfect choice.

FAQs

What makes CNC-machined components better than factory-made parts?

CNC-machined components are crafted with extreme precision, ensuring a perfect fit and superior performance. Unlike factory-made or MIM (Metal Injection Molded) parts, CNC machining provides tighter tolerances, better durability, and a more polished finish.

Why is 416R stainless steel commonly used in Armory Craft products?

416R stainless steel is a high-grade material known for its strength, corrosion resistance, and machinability. These properties make it ideal for firearm components, ensuring long-lasting performance and minimal maintenance.

What are the key benefits of upgrading a carry-size firearm with CNC-machined components?

Upgrading with CNC-machined components enhances the firearm’s accuracy, reliability, and overall handling. These parts are designed to perform under pressure, making them perfect for everyday carry and self-defense situations.

Do CNC-machined components require special maintenance?

No, CNC-machined components do not require special maintenance. They are crafted from durable materials like stainless steel, which resists wear and corrosion. Regular cleaning and lubrication, as recommended for any firearm, will keep them in excellent condition.

Can I install Armory Craft CNC-machined components myself?

Yes, many Armory Craft components are designed for easy installation and can often be fitted by the firearm owner. However, for parts requiring precise alignment or professional tools, consulting a gunsmith is recommended to ensure proper installation.

Article Recommendations

Megan Essig Comply: A Journey of Dedication to Justice, Law, and Compliance

Catherine Carabetta’s Impact on Finance and Community Empowerment

XannyTech.net/: Your Guide to Technology, iPhone Tips, and Digital Creativity

ChannelSynCharma: The Future of Synchronized Digital Communication