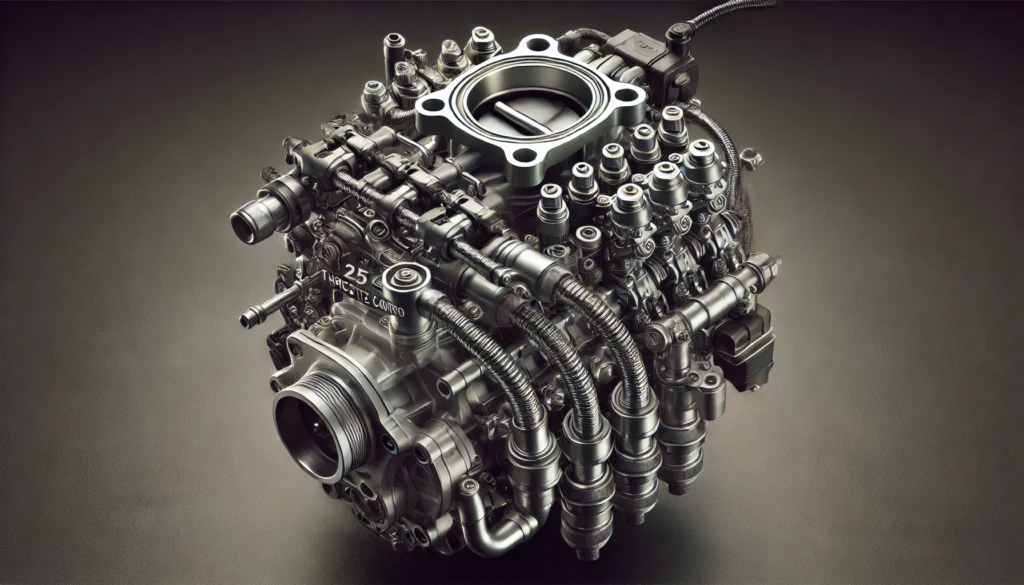

The K25LP throttle contro is a crucial component in modern engine management, responsible for regulating the amount of air and fuel mixture that enters the combustion chambers. This precise control directly impacts engine performance, power output, and fuel efficiency. Traditionally, throttle control was a mechanical system, where a cable connected the accelerator pedal to the throttle body.

However, with advancements in technology, systems like the K25LP throttle contro have shifted towards electronic throttle control (ETC). These advanced systems use sensors and actuators to manage throttle position, offering smoother acceleration, enhanced fuel economy, and better control, especially under demanding driving conditions. The K25LP throttle contro represents a significant leap in engine technology, optimizing performance while providing more reliable and responsive driving experiences.

How K25LP Throttle Contro Regulates Air and Fuel Mixture

The K25LP throttle contro plays a critical role in controlling the balance of air and fuel that enters the engine’s combustion chambers. By adjusting the throttle position, it regulates how much air flows into the engine, allowing the engine control unit (ECU) to precisely calculate the optimal fuel amount to inject. This ensures an ideal air-fuel mixture for combustion, which is vital for maintaining engine efficiency and performance. Proper regulation of this mixture also affects how the engine responds to acceleration, influencing everything from power output to fuel consumption, making the K25LP throttle contro a key component in engine management.

Impact of K25LP Throttle Contro on Engine Power

The K25LP throttle contro has a direct impact on engine power by controlling the flow of air entering the engine, which in turn influences the combustion process. When the throttle opens, more air is allowed into the combustion chamber, and the engine generates more power. Conversely, closing the throttle reduces airflow and limits power output. By providing precise control over air intake, the K25LP throttle contro ensures that the engine responds smoothly and efficiently to driver input. This improves overall engine performance, delivering better acceleration and power when needed, while also optimizing fuel usage under varying driving conditions.

K25LP Throttle Contro and Fuel Efficiency: What You Need to Know

Fuel efficiency is one of the primary benefits of the K25LP throttle contro system. By electronically regulating the air-fuel mixture, it ensures that the engine burns fuel more efficiently. Unlike older mechanical throttle systems, the K25LP throttle contro adjusts in real-time based on driving conditions, engine load, and driver input. This precision reduces unnecessary fuel consumption and helps maintain optimal fuel economy, especially during city driving and high-speed conditions. By minimizing fuel waste and maximizing combustion efficiency, the K25LP throttle contro not only lowers fuel costs but also reduces harmful emissions, making it an environmentally friendly option.

The Evolution from Mechanical to Electronic K25LP Throttle Contro Systems

In the past, throttle control was a mechanical system involving cables connected between the accelerator pedal and throttle body. As technology advanced, the K25LP throttle contro evolved into an electronic system, replacing the mechanical linkage with sensors and actuators. This change allows for more precise control over throttle position, improving both performance and fuel efficiency. The electronic system communicates with the engine control unit (ECU), which calculates the necessary adjustments in throttle position based on various inputs like speed, load, and driver demand. This evolution from mechanical to electronic systems has enhanced overall engine control, leading to smoother driving experiences and better responsiveness.

Benefits of Modern K25LP Throttle Contro for Engine Performance

Modern K25LP throttle contro systems offer several performance advantages over older mechanical systems. By using electronic sensors to manage throttle position, the system provides smoother acceleration, greater responsiveness, and improved fuel efficiency. The electronic control allows for real-time adjustments based on driving conditions, ensuring that the engine operates at optimal levels at all times.

Additionally, this system reduces wear and tear on mechanical parts, enhancing reliability and durability. Another key benefit is that it provides better control during high-performance driving situations, such as during rapid acceleration or when navigating steep inclines, where precise throttle input is critical for maintaining power and stability.

- Enhanced precision in controlling air-fuel mixture for optimal combustion

- Improved fuel efficiency through real-time throttle adjustments

- Smoother and more responsive acceleration during varied driving conditions

- Reduced mechanical wear due to electronic control, increasing system longevity

- Better engine power management, delivering more consistent performance

- Increased reliability with fewer moving parts compared to mechanical systems

- Improved engine performance under high-load conditions, such as towing or steep inclines

- Lower emissions by optimizing fuel consumption and combustion efficiency

How K25LP Throttle Contro Contributes to Smoother Acceleration

The K25LP throttle contro significantly improves acceleration by providing more precise control over the throttle opening. With its electronic sensors, the system can respond almost instantly to driver input, allowing for smoother transitions from idle to acceleration. Traditional mechanical systems, by comparison, often experienced delays or uneven throttle response.

The K25LP throttle contro continuously monitors engine conditions and adjusts the throttle position accordingly, delivering a more refined and responsive acceleration curve. This smoothness not only enhances the driving experience but also helps prevent unnecessary strain on the engine, improving longevity and reducing the likelihood of jerky or abrupt movements during acceleration.

- Instant throttle response due to electronic sensors and actuators

- Eliminates the delay found in traditional mechanical throttle systems

- Provides more gradual and controlled acceleration during rapid speed changes

- Continuously adapts to driving conditions for seamless transitions

- Reduces engine lag during gear shifts or sudden speed adjustments

- Ensures consistent power delivery without abrupt surges or drops

- Maintains smooth acceleration even in challenging terrains or inclines

- Enhances driver confidence and comfort by minimizing jerky movements

The Role of Sensors in K25LP Throttle Contro Technology

Sensors are a critical component of the K25LP throttle contro, enabling the system to adjust throttle position with precision. These sensors monitor variables such as throttle position, engine speed, air intake, and driver input from the accelerator pedal. The information is sent to the engine control unit (ECU), which processes the data and makes real-time adjustments to optimize performance and efficiency. By using sensors, the K25LP throttle contro can achieve a level of accuracy and responsiveness that mechanical systems cannot match. The sensors also help detect issues early, improving the system’s reliability and ensuring that the engine operates smoothly under varying driving conditions.

Why K25LP Throttle Contro Ensures Better Control in Challenging Driving Conditions

The K25LP throttle contro provides better control in challenging driving conditions by offering more precise and responsive throttle adjustments. Whether you’re driving on steep inclines, navigating tight corners, or accelerating on slippery surfaces, the electronic system adapts quickly to maintain stability and performance. It continuously monitors driving conditions and adjusts the throttle position to ensure smooth power delivery, preventing sudden surges or drops in power that could lead to loss of control. This enhanced control not only improves driver confidence but also reduces the risk of accidents, making the K25LP throttle contro particularly beneficial in adverse weather conditions or rough terrains.

K25LP Throttle Contro: A Key Component in Electronic Throttle Management

The K25LP throttle contro is an essential part of modern electronic throttle management systems, which have replaced traditional mechanical throttle controls. As a key component, it ensures that the throttle position is adjusted in real-time based on various inputs from sensors. This electronic system offers superior precision and responsiveness compared to mechanical systems, resulting in improved fuel efficiency, better engine performance, and enhanced drivability. By managing the air intake to the engine more accurately, the K25LP throttle contro helps achieve smoother acceleration, optimized power output, and better overall engine control, contributing to a more reliable and efficient driving experience.

Comparing Traditional Throttle Systems with K25LP Throttle Contro

Traditional throttle systems relied on a mechanical linkage between the accelerator pedal and the throttle body, whereas the K25LP throttle contro uses electronic sensors and actuators to manage throttle input. The older systems, while functional, lacked the precision and responsiveness of modern electronic systems. Mechanical systems often had delays or inconsistencies in throttle response, especially during rapid acceleration or high-performance driving. In contrast, the K25LP throttle contro provides real-time adjustments, ensuring smoother acceleration, better fuel economy, and more accurate control over engine power. Additionally, electronic systems reduce wear on mechanical parts, resulting in longer-lasting, more reliable throttle control.

The Importance of Precision in K25LP Throttle Contro Systems

Precision is one of the defining features of the K25LP throttle contro system. Unlike mechanical systems, which rely on physical components that can wear down or become less accurate over time, the K25LP system uses electronic sensors to measure throttle input and adjust air intake with exceptional accuracy. This precision leads to more efficient fuel consumption, better engine performance, and smoother driving experiences. It also enhances safety by providing the driver with more reliable control over the vehicle in a variety of conditions. By fine-tuning the air and fuel mixture entering the engine, the K25LP throttlecontro ensures that the engine operates at peak efficiency.

Future of Engine Control with K25LP Throttle Contro Technology

The future of engine control will likely see further advancements in K25LP throttle contro technology, as more vehicles adopt electronic throttle systems for enhanced efficiency and performance. With ongoing innovations in sensor technology, data processing, and machine learning, future iterations of the K25LP throttlecontro could offer even greater precision and adaptability. These advancements may include smarter systems that learn from driver behavior and environmental conditions to automatically optimize throttle response. Additionally, as electric and hybrid vehicles become more prevalent, the K25LP throttlecontro could evolve to manage energy consumption more efficiently, contributing to both performance and sustainability in the automotive industry.

Troubleshooting Common Issues with K25LP Throttle Contro Systems

While the K25LP throttle contro system is highly reliable, occasional issues can arise, such as sensor malfunctions, electronic control failures, or throttle position errors. Common symptoms of these problems include delayed throttle response, poor acceleration, or inconsistent engine power. To troubleshoot, it’s important to check for any warning lights on the dashboard, as modern vehicles often include diagnostic systems that can detect throttle control issues. If a sensor is faulty, it may need to be recalibrated or replaced. Regular maintenance, such as cleaning the throttle body and inspecting the wiring, can prevent most issues and ensure the K25LP throttle contro operates smoothly.

Final Thoughts

The K25LP throttle contro represents a significant advancement in modern engine control systems, offering improved precision, smoother acceleration, and enhanced fuel efficiency compared to traditional mechanical systems. Its ability to regulate the air and fuel mixture with electronic sensors ensures that engines perform optimally under a wide range of driving conditions. As automotive technology continues to evolve, the K25LP throttle contro system will likely play an even more critical role in achieving greater performance, sustainability, and control. Whether in everyday driving or challenging environments, this system provides drivers with confidence and efficiency, contributing to a safer, more enjoyable driving experience.

FAQs

What is the primary function of the K25LP throttle contro?

The K25LP throttle contro manages the air and fuel mixture entering the engine’s combustion chambers, directly influencing engine performance, fuel efficiency, and power output. It uses electronic sensors to make precise adjustments based on driving conditions and driver input.

How does the K25LP throttle contro improve fuel efficiency?

By electronically regulating the air-fuel mixture with precision, the K25LP throttle contro ensures that the engine operates at optimal efficiency. It adjusts in real-time, preventing excess fuel consumption and enhancing fuel economy, especially during acceleration and deceleration.

What are the advantages of electronic throttle control over mechanical systems?

Unlike traditional mechanical systems, the K25LP throttle contro uses sensors and actuators to manage throttle position. This leads to smoother acceleration, more precise control, better fuel efficiency, and less wear on mechanical components, making it more reliable and durable.

Can the K25LP throttle contro system malfunction, and what should I do if it does?

While the K25LP throttle contro is highly reliable, issues can occur, such as sensor malfunctions or electronic failures. Symptoms include delayed acceleration or warning lights. Regular maintenance, such as throttle body cleaning and sensor checks, can help prevent problems. If an issue arises, consult a mechanic or diagnostic tool.

Will the K25LP throttle contro work with hybrid or electric vehicles?

Yes, as engine technology continues to evolve, the K25LP throttle contro can adapt to hybrid and electric vehicles. In these applications, it can help optimize energy consumption and improve performance, making it a versatile system for modern automotive advancements.